Hardfacing is low cost method of deposing wear resistand surfaces of metal components to extend service life.

Although used primarity to restore worn parts to usable condiction, hardfacing is also aplied to new componets before being placed into service.

In addition to extending the life of new and worn components, fardfacing provides the following benefits:

• Fewer replacement parts neeced.

• Operating efficiency is increased by reducing downtime.

• Less expencive base metal can be used.

• Owerall costs are reduced.

SRS offers a complete range of hardfacings for the various drilling conditions:

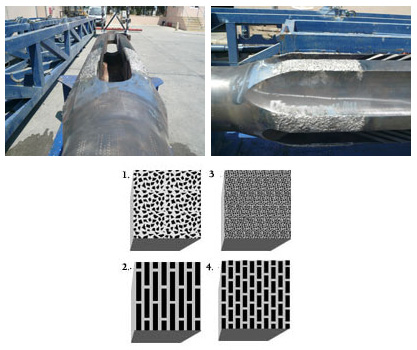

| 1. | Tungsten - Best in soft to medium-hard formations and on welded blade stabilizers. Crushed tungsten in nickel bronze matrix. |

| 2. | Half Rounds with Tungsten - Ideal for high deviation drilling in abrasive formations. Trapezoidal tungsten carbide inserts in a sintered carbide nickel bronze matrix. |

| 3. | Stabil-Tech™ - A finer matrix than Premium which suspends fine tungsten carbide with a hardness to 2500 HV in a hard, ferrous matrix. The matrix will attain a hardness level of over 45 HRC. |

| 4. | Quick Tip Hardfacing - The most cost-effective way to apply the maximum amount of high-grade tungsten carbide on any wear surface. Also available in multiple thicknesses. The bonding between hardfacing and base material can be verified by ultrasonic inspection |